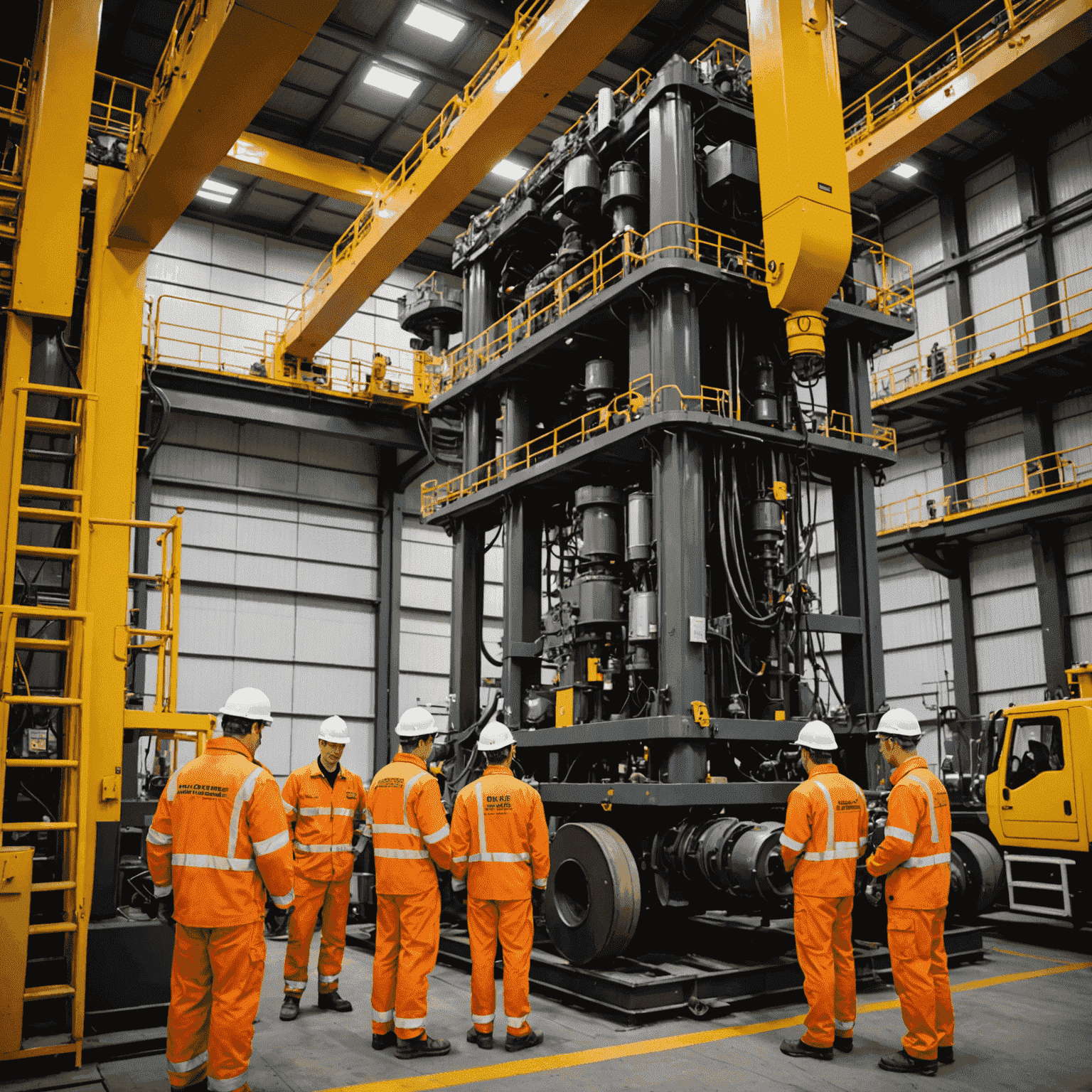

Preventive Maintenance: The Key to Longevity

In the oil industry, where equipment reliability is paramount, preventive maintenance emerges as a critical strategy for extending the lifespan of oil equipment and maximizing operational efficiency. This approach not only ensures the longevity of valuable assets but also contributes significantly to the profitability of oil operations.

Understanding Preventive Maintenance

Preventive maintenance involves regular, scheduled inspections and services designed to detect and prevent potential issues before they escalate into major problems. For oil equipment, this proactive approach is essential in maintaining optimal performance and avoiding costly breakdowns.

Key Benefits of Preventive Maintenance

- Extended equipment lifespan

- Reduced downtime and production losses

- Improved safety for workers and the environment

- Lower long-term maintenance costs

- Enhanced operational efficiency

Implementing an Effective Preventive Maintenance Program

To maximize the benefits of preventive maintenance, oil companies should consider the following steps:

- Develop a comprehensive maintenance schedule: Create a detailed timeline for inspecting and servicing each piece of equipment.

- Utilize condition monitoring technologies: Implement sensors and data analysis tools to track equipment performance in real-time.

- Train maintenance staff: Ensure that technicians are well-versed in the latest maintenance techniques and technologies.

- Keep detailed records: Maintain thorough documentation of all maintenance activities and equipment history.

- Regularly review and update procedures: Continuously refine maintenance practices based on equipment performance and industry advancements.

The Impact on Profitability

Investing in preventive maintenance can significantly boost profitability in the oil industry. By reducing unexpected breakdowns and extending equipment life, companies can minimize production losses and capital expenditures on new equipment. This approach aligns perfectly with the goal of generating sustainable income from oil operations.

Conclusion

Preventive maintenance is not just a cost-saving measure; it's a strategic investment in the longevity and efficiency of oil equipment. By prioritizing this approach, oil companies can ensure their operations remain profitable, safe, and sustainable in the long term. As the industry continues to evolve, those who master the art of preventive maintenance will be best positioned to thrive in the competitive landscape of oil equipment services.